Hydraulic Press Machine: Power, Precision, and Practical Uses Explained

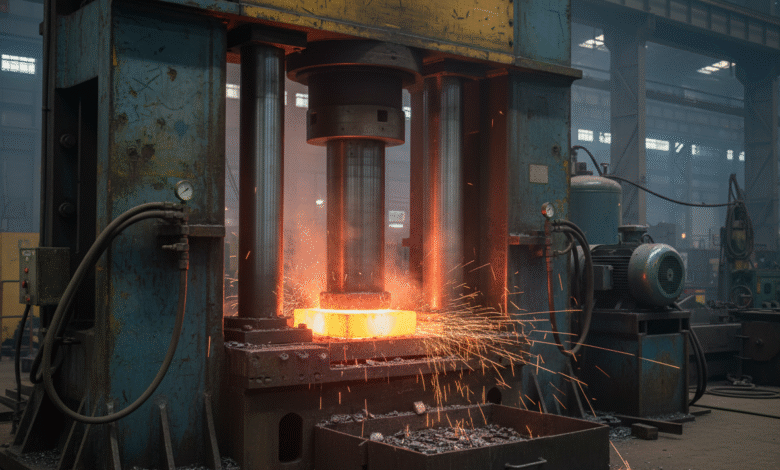

A hydraulic press machine is one of those powerful tools that quietly shapes the modern world. From factories and workshops to laboratories and recycling plants, this machine plays a key role in forming, shaping, crushing, and assembling materials with impressive force and accuracy. At first glance, it may look simple, but behind its solid frame lies smart engineering, reliable physics, and decades of industrial experience.

This article takes a deep, reader-friendly look at the hydraulic press machine, explaining how it works, where it is used, its types, benefits, safety tips, and future trends. Written in clear Grade 7 English, this guide is designed to build trust, show expertise, and help you truly understand why this machine matters so much.

What Is a Hydraulic Press Machine?

A hydraulic press machine is a mechanical device that uses liquid pressure to generate a large amount of force. It works based on Pascal’s Principle, which states that pressure applied to a confined fluid is transmitted equally in all directions.

In simple terms:

- A small force applied to a small piston

- Creates a much larger force on a bigger piston

That’s the magic behind the hydraulic press machine.

Because of this principle, the machine can press, bend, punch, compress, or shape materials like metal, plastic, rubber, and even wood with ease.

How a Hydraulic Press Machine Works

Understanding how a hydraulic press machine works doesn’t have to be complicated. Let’s break it down step by step.

The Basic Working Principle

The machine mainly consists of:

- Two cylinders (small and large)

- Hydraulic fluid (usually oil)

- Pistons

- Pump and control valves

When pressure is applied to the small piston:

- The hydraulic fluid transfers that pressure

- The larger piston moves with much greater force

This allows the machine to perform heavy-duty tasks with smooth and controlled motion.

Why Hydraulic Fluid Is Important

Hydraulic fluid:

- Does not compress easily

- Transfers pressure efficiently

- Helps cool and lubricate the system

Without this fluid, the hydraulic press machine simply wouldn’t work.

Key Components of a Hydraulic Press Machine

A reliable hydraulic press machine is built from strong, carefully designed parts. Each component plays an important role in performance and safety.

Main Components Explained

- Frame: Supports the entire machine and absorbs force

- Hydraulic Cylinder: Creates linear motion

- Pistons and Rams: Apply pressure to the workpiece

- Hydraulic Pump: Moves the fluid through the system

- Valves: Control pressure, direction, and speed

- Control Panel: Allows the operator to manage operations

Together, these components ensure smooth operation and long service life.

Types of Hydraulic Press Machine

Not all hydraulic presses are the same. Different industries require different designs. Here are the most common types of hydraulic press machine used today.

Common Types

- C-Frame Hydraulic Press Machine

Compact and easy to use, ideal for small workshops. - H-Frame Hydraulic Press Machine

Heavy-duty and stable, used for industrial applications. - Four-Column Hydraulic Press Machine

Offers high precision and even force distribution. - Bench-Type Hydraulic Press Machine

Small and portable, suitable for light tasks. - Automatic Hydraulic Press Machine

Uses advanced controls for high-volume production.

Each type serves a specific purpose, making the hydraulic press machine a flexible solution across industries.

Industrial Applications of a Hydraulic Press Machine

The hydraulic press machine is a true workhorse. It’s used in many industries, often behind the scenes.

Major Industries That Rely on Hydraulic Press Machines

- Manufacturing and Metalworking

- Bending metal sheets

- Punching holes

- Forming components

- Automotive Industry

- Assembling car parts

- Pressing bearings and bushings

- Shaping body panels

- Construction

- Forming concrete blocks

- Shaping steel structures

- Recycling Industry

- Crushing cans

- Compressing scrap metal

- Laboratories and Research

- Material testing

- Sample preparation

No matter the field, the hydraulic press machine gets the job done efficiently.

Advantages of Using a Hydraulic Press Machine

There’s a reason why industries prefer the hydraulic press machine over mechanical alternatives.

Key Benefits

- High Force Output

Produces massive pressure with minimal input. - Smooth and Controlled Operation

Reduces material damage and improves accuracy. - Energy Efficient

Uses power only when needed. - Versatile Usage

Handles a wide range of materials and tasks. - Low Maintenance

Fewer moving parts mean less wear and tear.

In short, it’s powerful, dependable, and cost-effective no wonder it’s so popular.

Safety Measures When Using a Hydraulic Press Machine

While a hydraulic press machine is incredibly useful, it must be handled with care. Safety is not optional it’s essential.

Important Safety Guidelines

- Always wear protective gear

- Never exceed pressure limits

- Inspect hoses and seals regularly

- Keep hands away from moving parts

- Use emergency stop features when needed

A well-maintained machine combined with trained operators ensures safe and smooth operations every time.

Hydraulic Press Machine Specifications at a Glance

Below is a simple table to help you understand common specifications of a hydraulic press machine.

| Feature | Description |

|---|---|

| Press Capacity | Measured in tons (10–500+ tons) |

| Stroke Length | Distance the ram travels |

| Working Pressure | Maximum hydraulic pressure |

| Power Source | Manual, electric, or pneumatic |

| Control Type | Manual, semi-automatic, automatic |

| Frame Material | Heavy-duty steel |

This table highlights why choosing the right hydraulic press machine matters for your specific needs.

Maintenance Tips for a Hydraulic Press Machine

Good maintenance keeps a hydraulic press machine running smoothly for years.

Simple Maintenance Practices

- Check hydraulic fluid levels regularly

- Replace worn seals and hoses

- Keep the machine clean

- Inspect valves and pumps

- Follow manufacturer guidelines

A little care goes a long way. After all, prevention is better than cure.

Modern Innovations in Hydraulic Press Machine Technology

Technology keeps moving forward, and the hydraulic press machine is no exception.

Latest Developments

- CNC Integration for higher accuracy

- Smart Sensors for pressure monitoring

- Energy-Saving Systems

- Improved Safety Controls

- Eco-Friendly Hydraulic Fluids

These innovations make today’s hydraulic press machines smarter, safer, and more efficient than ever before.

Choosing the Right Hydraulic Press Machine

Picking the right hydraulic press machine can feel overwhelming, but it doesn’t have to be.

Factors to Consider

- Required force capacity

- Type of material

- Available workspace

- Level of automation

- Budget and maintenance costs

When these factors align, you’ll get a machine that fits like a glove.

Environmental Impact of a Hydraulic Press Machine

Modern industries are paying more attention to sustainability, and the hydraulic press machine is adapting too.

Eco-Friendly Aspects

- Reduced energy consumption

- Long operational life

- Recyclable components

- Lower noise levels

With proper design and usage, hydraulic press machines support greener manufacturing practices.

Common Myths About Hydraulic Press Machines

Let’s clear up a few misunderstandings.

- Myth: Hydraulic presses are outdated

Fact: They’re evolving with advanced technology. - Myth: They’re dangerous by design

Fact: With safety measures, they’re very safe. - Myth: Maintenance is difficult

Fact: Routine care is simple and affordable.

Knowing the truth helps users make better decisions.

Final Thoughts on Hydraulic Press Machine

The hydraulic press machine is a powerful symbol of engineering efficiency. From its simple working principle to its wide range of applications, it continues to support industries across the globe. It’s strong yet precise, complex yet reliable, and old in concept but modern in execution.

As industries grow and technology advances, the hydraulic press machine remains a trusted companion doing the heavy lifting without complaint. Whether you’re a student, engineer, business owner, or curious reader, understanding the hydraulic press machine gives you insight into one of the most important tools of modern manufacturing.

In the end, the hydraulic press machine proves that when science, experience, and smart design come together, incredible things happen and that’s no exaggeration at all.

You may also read

Jeff Bezos Girlfriend: A Complete, In-Depth Look at His Life Partner and Their Journey Together